- Over 20 years experience in bag manufacturing

- Our China bag factory exported to more than 50 countries

- Annual production is over 5 million

- Two production bases and more than 300 workers

- OEM/ODM service for many world famous brands

- Self-contained process of quality management

HIGH END QUALITY

PRODUCT DESIGN

STABLE DELIVERY TIME

PRECISE MANAGEMENT

BEST PRICE

7-24 SERVICE

CUSTOM BAG SUPPLIER

China bag factory of honeyoung

China bag factory of Honeyoung currently has two production bases of bag products. These two production bases cover an area of over 70,000 square meters, with more than 300 staff. Every year, more than 800 million bags are manufactured in our factories and sold around the world.

Our factory is equipped with first – class production facilities, and we passed authentications like ISO9001,SGS, SEDEX,DISNEY,BSCI certifications etc.

Honeyoung can make samples according to your product requirements and produce all kinds of bags, such as backpacks, computer bags, school bags, children bags, drawstring bags, lunch bags, duffel bags, etc.Hundreds of bag elements can be customized, please refer to our customization service or contact us for more details.

We are glad to introduce our factory via videos. You are also welcomed to visit our factory in person at any time.

How we produce

Our bag factory In CHINA

China Bag Factory of Honeyoung

Automatic Cutting Machine Of Honeyoung

Screen Printing Workshop

Sewing Workshop

Sewing Workshop

Sewing Workshop

Sewing Workshop

Sewing Workshop

Inspection Workshop

Custom Bags

quality management system of China bag factory

Our quality management system will monitor every detail, From business negotiation to service process.

Sealing samples

After confirming the samples made according to the customer's requirements, we will seal the samples with sample lock. All subsequent production will be carried out according to this confirmed sample.

Raw material inspection

To ensure quality, Our raw material purchasing personnel will check all the raw materials before they enter the warehouse. Color and quantity of these raw materials are consistent with the customer's order.

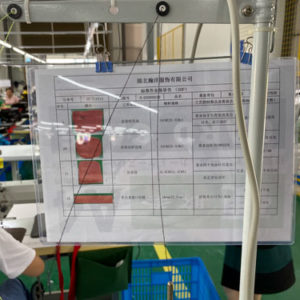

Production operation instruction

There is a production instruction on the desk of each worker, which include the current production process requirements of the worker, including pictures, process name, material specifications, process control points and self-inspection standards.

Finished product inspection

After finishing the sewing process, the products will go through the needle testing machine to the finished product quality inspection workshop. Needle testing machine can ensure that the products delivered to customers without broken needles and metal debris, to ensure the safety of consumers. Products will be cut off in the quality inspection workshop, qualified products will be transferred to the next step for packaging, defective products will be allocated to the production line for rework or repair.

Packing inspection

Products will be packaged in accordance with the customer's packaging requirements, after packaging, the products will be delivered.

CRAFTING

Customization Service of China bag factory

As a professional bag factory in China, we own 10 production lines (over 300 workers in total). the minimum order quantity of us is 500 units. We provide customized services (logo design and customization, packaging customization) based on our offered models. If you want us to do that on your models, we can do that as well. As a professional bag manufacturer, We’ll design or improve your backpack products through these services:

- Bag products design suggestions: measurement, fabrics, function, color collocation,LOGO customized, packaging and defects removal, etc.

- Sales volume prediction: years of working experiences with clients from all over the world has made us a sharp observation in B2C product selection.

- Production phase: to tell you how long will it take to deliver your order.

If you need no bag products customization, we can offer all types of hot selling bag products in stock.

- LOGO CUSTOMIZATION

- MATERIAL CUSTOMIZATION

- Color CUSTOMIZATION

- PACKAGING CUSTOMIZATION

Metal Logo

Embroidery Logo

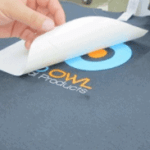

Heat Transfer Printing

Zipper Pull Logo

Inner Label

Rubber Logo

Silk Printing

Velcro Patch Logo

Wash Care Logo

Embossed Logo

Polyester

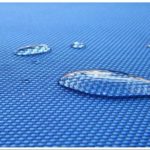

Oxford

Non-Woven

Nylon

Canvas

RPET

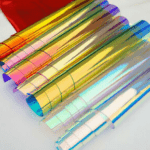

PVC

PU Leather

Linen

Cotton Cloth

Solid Carton

Labeled Carton

Paper Box

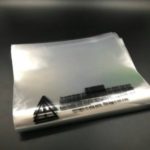

Opp Bag

Customized Hangtag

Opp With Custom Warning

BAG MANUFACTURER

Production equipment of honeyoung

Full-automatic Cutting Machine

Two-needle Computer Plain Seam Machine

Synchronous Sewing Machine

Bartacking Machine

High Machine

Computer Pattern Machine

Computer Pattern Machine

Ironing Machine

Needle Inspecting Machine