How do bag manufacturers produce bags? China has the largest and the most comprehensive manufacturing industries in the world. In order to explore how bag products are made, today we come to Honeyoung bag factory to find the answer.

- Bag Design

- Sample Making

- Confirming purchasing list and product SOP

- Start producing bags & confirming samples

Bag Design

Design and Communication

Our clients usually have their own designs or samples for us to make. But there are also some clients who don’t have their own design team, so we can provide bag design services. We have professional bag designers for product design. The first step in bag design is to confirm customer’s needs. What the product aimed at? Color selection? Fabric choice? Internal and external structure? Waterproof and load-bearing requirements? These are the information that needs to be discussed with the purchasing customer before designing the bag product. These details directly affect whether a product can become a hot seller.

Every month we have a catalogue of new products, which are designed by our designers according to the latest trends and popular products in various markets. If you are interested in this, please email us and we’ll send you a catalog of new products every month.

Draw a preliminary draft

After drawing the draft, the bag designer will communicate with client to see if the client has any suggestions for modification. After analyzing opinions, our designers will make changes until the final design data is confirmed. We will publish a blog to share how designers design bags.

Choosing materials for bag

Raw materials should be selected before sample making. The design draft can only manifest the size, color and structure of the product. The actual texture of the product depends on the choice of raw materials. Our designers will choose the selection range of raw materials for customers’ reference according to the design requirements of customer. Fabric, LOGO, zipper, fastener, hanging card and so on can be customized.

In the case of fabrics, different choices have different effects. If it is a computer case, we recommend to use 1680D fabric, which is wear-resistant and scratch-resistant, together with the cushion sponge inside, can well protect our computer from damage. For student backpacks, we recommend using 600D Oxford cloth. This material is characterized by light weight, good load-bearing force, and relatively cheap price, which is completely enough to meet the daily use of students.

We choose raw materials according to the original intention of product design, which can make the product more practical, so as to meet the habits of users.

Sample Making

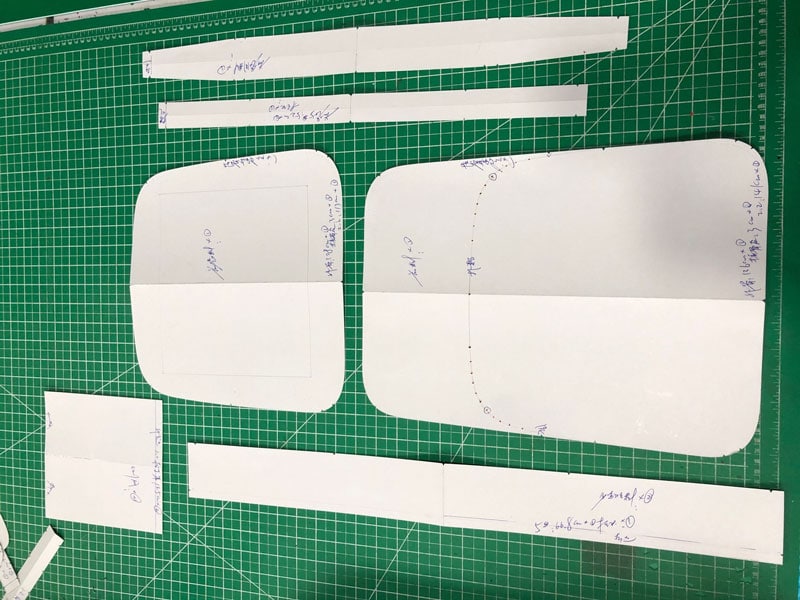

After the draft and material selection are completed, the data will be collected into a list of data and submitted to the sample maker. The sample maker will cut the fabric into the corresponding parts and then sew the parts together to make a complete backpack. If you are interested in it, you can read our article: How Does A Backpack Go From Sketch To Reality.

The meaning of the bag sample is to allow designers and clients learning more details about the product, after all, draft can only shows a small amount of defects or deficiencies. The confirmed samples are also the basis for mass production and the standard for quality inspection of finished products.

Confirming purchasing list and product SOP

Purchasing list of raw materials

After the customer confirmed all the data of the bag, our purchasing agent will make the purchasing list. The amount of fabric, lining, webbing, cotton, fasteners and hanging cards for the order should be listed in detail. After the production manager reviewed the purchasing, the purchasing manager will finally begin to purchase.

Some materials are out of stock. It usually takes 15-35 days to produce for you. During this process we can do many other things, such as making the product SOP.

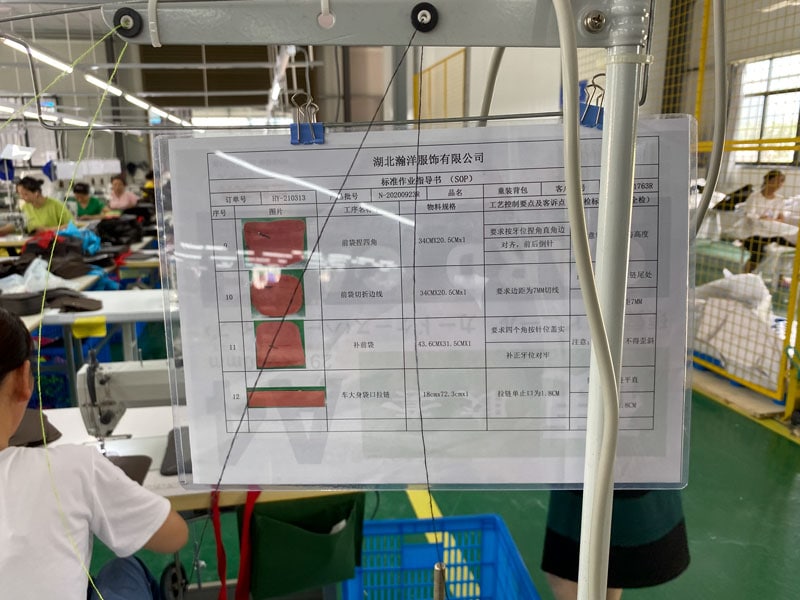

SOP of Honeyoung bag factory

What is SOP? SOP refers to the description of Standard Operating Procedure, which is used to guide and regulate work. Our SOP runs through the whole process of sample making, purchasing, production, quality inspection and packaging, we have perfect quality management system.

Bag production is a labor-intensive industry that requires many workers. Production levels are varied among them, and that leads to differences in bag quality. In order to ensure that the products can be delivered to customers with high quality, we have SOP in every step of production. Workers in different steps have different SOP at their stations. Our SOP contains name, production requirements and quality inspection standards, which are accurate within 0.3cm.

Start producing bags & confirming samples

When the raw materials are all set, our factory will check the raw materials. The content of quality inspection includes color difference, weight standard, size. After that, our production can finally begins.

Cutting

We have already determined the size and shape of each piece of fabric during sample making. Then, we’ll cut the whole roll of fabric according to the measurement. Cutting fabric is a very important part of the process. We need to make the pieces precise and not to waste too much fabric.

In order to further reduce the purchase cost and thus reduce the purchase price of customers, we have imported a fully automatic cutting machine. It can cut the fabric through accurate calculation. It not only improves the efficiency of fabric cutting, but also maximizes the loss of fabric.

Sewing production

All the cut fabrics will come into our workshop and be distributed to the workers. The workers will sew the semi-finished products according to the SOP. Generally, there are 15 workers in one production team, and a production team corresponds to 1-3 production links. The work of different production teams is combined to create a complete production process of a bag. Such mass production can greatly improve efficiency.

Each team has a production leader, who checks on the production line to see if the semi-finished products meet quality standards. Moreover, the group leader will also provide technical guidance to workers to improve their efficiency. At the end of the day, the team leader needs to count the output of all the team members.

The semi-finished product will eventually flow to the workers who use post bed sewing machine. The workers combine the semi-finished products into a bag body. At this point, the backpack has an initial look, but it’s not complete. Workers also need to install straps on the fasteners, zippers. So far, the backpack is completed.

For readers interested in logo customization, please check out our upcoming article “How to Customize Logos on Bags”

Quality control and packaging

We‘ll do a variety of tests on the first batch , including checking for defects,size and bearing capacity. If all tests are passed, then the product can be delivered.

All finished products will be transferred to quality inspection workshop, and the workers will inspect each backpack to make sure they are all set. If the product is defective, it will be put in the red box and sent back for rework. If the product is qualified, it will be transferred to the packing workshop in blue box.

The packing worker is responsible for attaching hangtags to each bag, and sealing it in OPP bags. We will box according to customer’s shipping requirements. Generally a carton can contains about 30 backpacks, of course, the number is based on the specific size of the backpack. We guarantee that we never waste any space in the carton, otherwise it will waste the freight.

Bag production is not just a couple of man working in a room. From Design to shipping, every department in the company has to involved in. Anhui Honeyoung, a bag manufacturer with decades of history, is already concluded many experiences of bag production and always ready to help you. Please contact us if you are interested in us.