1. What is RPET?

Before we begin to introduce what RPET is, let’s start with what PET is. This is an acronym representing a long-term: polyethylene terephthalate, a polymer of ethylene glycol and terephthalic acid. PET is a common plastic resin. Producers use crude oil and natural gas to make PET and then heat and turn it into liquid. The liquid can be spun into fibers to make polyester fabric, and it can also be made into PET containers.

The letter “R” in “RPET” represents the word “Recycled”. RPET stands for recycled PET material.

It is one of the four largest plastics in the world. It is non-toxic and can be used to pack food, as well as make clothes, backpacks, shopping bags and other products.

2. The generation process of RPET

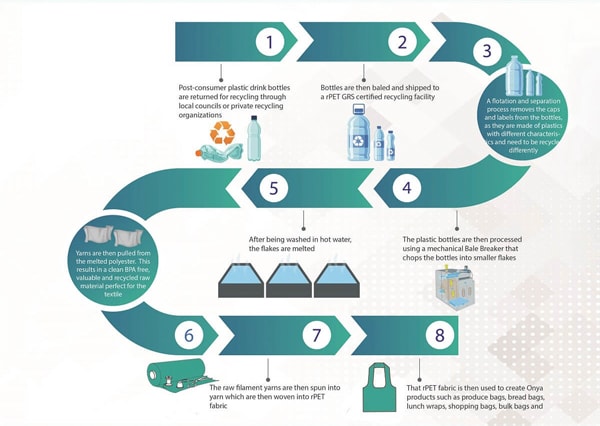

2.1 Recycle beverage bottles of 100% RPET to RPET production sites.

2.2 Use equipment to remove labels and caps and clean beverage bottles.

2.3 Use special machinery to cut beverage bottles into fine particles.

2.4 They go through a de-polymerization and re-polymerization process to be turned into PET chips. These PET chips or pellets can be used to make clothing, insulation, new water bottles, etc.

2.5 The pellets are then passed through a spinneret and melted and cooled into fibers, which are then smoothed, stretched and placed on reels in order to make yarn.

2.6 The yarn is ready to be used in fabric again and has the same aesthetics and functional performance as conventional polyester yarn.

2.7 RPET fabric is made into backpacks, shopping bags, tents, cushions and other products.

3. How does RPET alleviate plastic pollution

RPET is made up of ready-made plastic, such as a bottle, which is split into tiny flakes or pellets and then melted down to separate the core PET inside the bottle. PET can be used to make clothing or plastic bottles. This saves more than 80% more energy than producing PET from scratch, and, using off-the-shelf plastic bottles, ensures that the bottles are not recycled directly and will not end up in landfills. It also means that we can leave the earth as it is and do not have to overpump crude oil to get other core PET elements.

4. Common products made of RPET

Many of the things we use in our daily life are actually made of RPET. Reusable shopping bags, folding backpacks, and some clothes are made by RPET. Bedding, pillows, outdoor items, sportswear, swimwear, cushions, insulation fibers, plastic bottles, food containers and stuffed toys are actually RPET products. RPET is much more versatile than we thought.

5. Why RPET ?

Reducing plastic use matters most, but it is also important to continue recycling the plastic already produced. RPET may not solve all our problems, but it’s still a better choice than the original PET. By purchasing RPET, you can support the plastic recycling industry and help create a market for recyclable plastics. Using RPET makes it unnecessary to entail raw materials, which reduces energy consumption and thus carbon footprint.

One plastic bottle (600cc) = reducing carbon emission 25.2g = saving fuel 0.52cc = saving water

RPET uses plastic waste that ends up in landfills and, what is even worse, it pollutes the environment. When discarded in landfills, plastic can take hundreds of years to decompose. When they break down, they tend to break down into smaller pieces that could cause more harm if released into the environment. The use of RPET is to make these materials that is hard to degrade get recycled, and avoid resource waste and environmental pollution, contributing to the environmental protection of the earth.

6. Disadvantages of RPET

Mechanical recycling, such as cleaning, shredding and melting PET plastic, weakens the plastic and causes it to discolor.

Recycled plastics used to make textiles release microplastics when they are washed. These microplastics end up in the ocean and cause pollution.

Others argue that recycling PET plastic blinds us to the nature of the problem — our dependence on plastic, with most of the world’s plastic still not being recycled for lack of technology, infrastructure or economic reasons.

There are difficulties in the coloring process due to impurities in the recycled material. This makes it difficult for RPET materials to keep the same color in different batches.

7. Application of RPET in bag industry

RPET is widely used in bag factories. Because of the high quality and moderate cost of polyester fabric made by RPET, these plastics have a new application in Honeyoung bag factory. The recycled polyester fabric can be used to make products such as backpacks, duffle bags, drawstring bags and reusable shopping bags.

Nowadays, many European countries require businesses to purchase products made of RPET materials as much as possible due to environmental issues. However, there is an unavoidable disadvantage of RPET material for merchants: currently, the cost of polyester fabric made of RPET is higher than that of ordinary polyester fabric made of petroleum.

Buying RPET productions is doing contributions to our planet Earth. As a professional bag manufacturer, Honeyoung feels obliged to recommend this kind of material. Any problems please feel free to contact us.