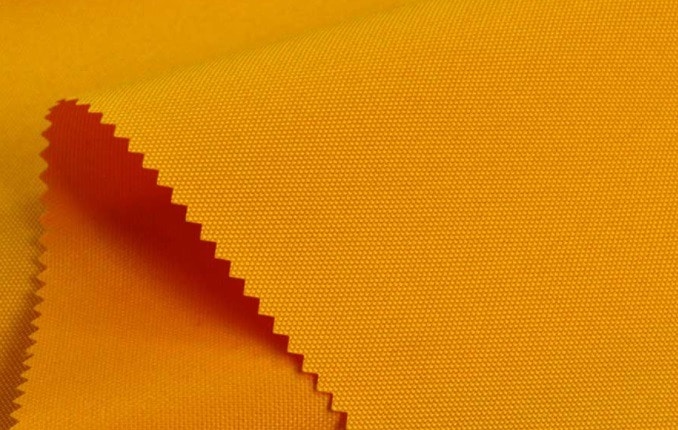

1. What is 600D polyester and what does the D means?

Before we explain 600D polyester, we need to know what the D means in 600D polyester. Many of you may believe that the D refers to density, but it’s not. D refers to denier, and denier is the measurement of fiber. If a thread is 9000 meters per gram, we call it a denier. The lower the D, the lower the density, and the thinner the thread. For example, 210D polyester has a thinner thread, suitable for the inner part of the bag. 900 D or 1000D has a thicker thread, harder and more durable, these can be used in making bag bottoms.

Fabrics with lower deniers are better than those with higher deniers, and fabrics with higher deniers are stronger. Polyester with higher deniers is usually stronger than those with lower deniers. 600D polyester is proven to be a modest fabric in bag making.

2. Advantages of 600D polyester

2.1 Affordable Cost

Since we are a source factory in China, if we control the cost at a relatively low level, our customers will get a lower price. With quality being guaranteed, 600D polyester is the best fabric at a low cost.

2.2 Suitable for making high-quality bag products

Cheap doesn’t mean bad performance, on the contrary, the 600D polyester is even used for making top-quality backpacks, and many world-famous bag suppliers choose it, including Osprey and Jansport.

2.3 Durable and enough thickness

600D polyester fabric is remarkably durable, it endured a series of professional tensile tests, and proved to be a fine material in the bag industry. Its enough thickness makes it can be widely used in many parts of bags. Thickness is not the thicker the better, because a thick material will be hard to bend, while bags need to be soft and flexible.

3. Disadvantages of 600D polyester

3.1 Easier to buildup static electricity

Due to its physical characteristics, polyester is easy to create static electricity when rubbing with other things. During dry winter, it’s very likely to get shocked by static electricity.

3.2 Hold odor longer compared to natural fiber

As we all know, newly made bags always have a little unpleasant smell. And natural fiber like cotton will be odorless within a couple of days. Polyester will take longer to be odorless, but finally it will. A fine quality 600D polyester should be odorless after 7 days of use.

3.3 Polyester is not very breathable

Compared to cotton fabrics and other natural fibers, polyester is not very breathable. Nowadays, fabric manufacturer has blended polyester with other fiber to improve breathability. Moreover, on casual occasions, durability is more important than breathability, 600D polyester will make everyone satisfied except for outdoor use.

4. What’s the difference between 210D, 600D and 1000D polyester?

210D polyester is soft and thin, it is not as durable and tear-resistant as 600D polyester. It is widely used in making the lining of the bag and drawstring backpacks.

600D polyester is lower in denier than 1000D polyester. 1000D polyester performs better in abrasion resistance than 600D polyester. Generally, we use 1000D polyester in luggage case and backpack making.

Backpack manufacturer will recommend suitable fabrics based on the customer’s product. If it is a high-grade hiking backpack, it will generally use 1000D. If it is a school bag, it is common to use 600D. 210D fabric is suitable for the lining of backpacks or suitcases.

5. What product is 600D polyester suitable for?

600D polyester is cheap and durable, very suitable for making school backpacks, drawstring backpacks, kids’ backpacks, and casual backpacks. These backpacks are not used in extreme conditions, so the material will meet your need just fine. Although there are lots of fabrics in options, the 600D polyester still stands out because of its cost performance.

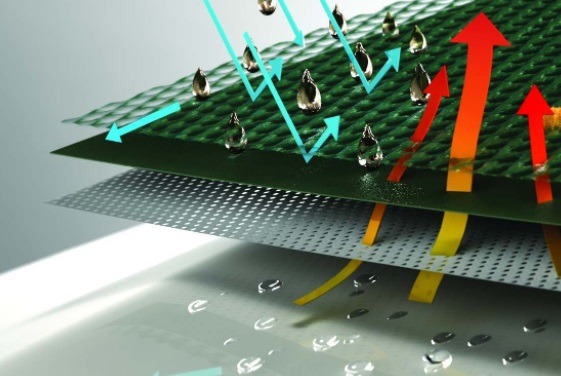

6. What’s the difference between 600D/PVC and 600D/PU?

PVC and PU are two commonly used coatings on 600D fabric.

PVC coating will increase the thickness of 600D fabric and improve its firmness. Therefore, under normal circumstances, we recommend customers make 600D/PVC fabric and use it on backpacks.

PU coating is usually used only when backpacks are printed with large patterns. Because patterns are printed on the fabric at high temperatures, the coating could be melted if applying PVC. Use 600D/PVC fabric to produce a pure color backpack, and use 600D/PU fabric to produce a big pattern backpack.

7. Where to buy 600D polyester fabric?

7.1 Alibaba

Alibaba from China is definitely one of the best raw material suppliers in the world. You can get everything you need in here. However, make sure you are choosing goods from verified suppliers. Many of them are middlemen, and the price could be higher, so verified suppliers like a company’s own factory will be better.

7.2 Guangzhou, Guangdong

The city has gathered many fabric suppliers, if you are an experienced purchaser, you probably get a good price in here. We recommend most for the experienced because many suppliers here are professional suppliers, and you could get tricked in price.

7.3 Honeyoung Bag

Finding suppliers on the web could be aimless. What if we say that you can get a one-stop service from material purchase to bag production? I believe that many of you will be happy to accept this chance. Here at Honeyoung, we can offer service like this, no need to worry about getting tricked. We are a professional bag manufacturer in China.

8. How to test the quality of the 600D polyester without professional equipment?

8.1 Density

Hold 600D fabric under sunlight to check for light leakage. If the light leakage is serious, it means that the fabric density is low.

Pull the fabric and check whether the fabric is badly deformed. If not, it means that the fabric density is high.

8.2 Scratch proof

Scratch the fabric 20 times with key. Check whether the fabric has an obvious scratch. If so, it indicates that the wear resistance of the fabric is poor.

8.3 Waterproof

600D polyester is waterproof, we can pour water on it to see how much water stains it gets.

8.4 Color retention

600D polyester can be dyed into various colors. We soak a piece of 5*5 CM fabric in water for 10 minutes. If the water is dyed, then the color retention of the fabric is not good.

Honeyoung bag has experienced 23 years in the bag production industry, if you have any questions, please feel free to contact us, and we’ll solve the problems for you.